-

Features

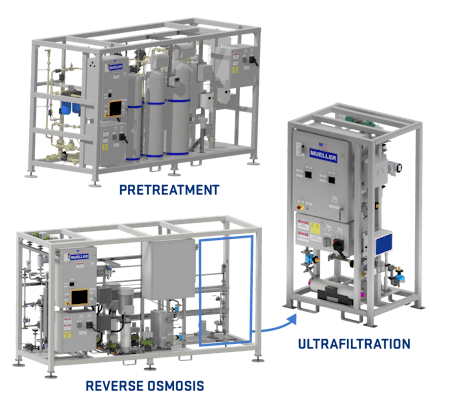

- Modularity

- Pretreatment (softener) skid includes dual pre-filters, dual softeners, a carbon filter, a UV light, and break tank

- RO and CEDI skid includes RO pre-filter, dual RO pumps, RO housings and membranes, and CEDI

- UF skid includes ultrafiltration (UF) and ultraviolet (UV)

- System can be purchased separately or as one system

- UF skid designed to fit within RO skid for footprint minimization

- Can oversize portions of the system to branch off the RO or softener system and feed other utilities in the facility if needed

- One centrally located control system

- UL508A Certified

- Distributed I/O capabilities

- Industrial hardened Ethernet backbone

- Fully supported by factory-certified service technicians

- Supported by in-house ISO 17025 calibration lab with onsite services

- Designed for sustainability

- Designed for pharmaceutical applications, including hot water sanitizable RO membranes

- Integrated control system controls the entire system and interfaces with other Mueller® water and steam systems

- No plant steam or coolant needed

- Includes recycling of water within the skid to minimize waste

- Fully operational, skidded, and tested at factory

- Reduces start-up time and site installation

- Factory performance tested

- Full pharmaceutical turnover package (TOP)

- Chemical-fee polypropylene butt-fusion welding for pretreatment skid

- Dual filters and softener tanks for a continuous supply of softened water for carbon & UV treatment in PT system

- Automated softening, carbon, & UV valving system based on defined water criteria

- Stainless steel tubing 25RA (SF2) for RO system & 20RA EP (SF5) for UF system

- Fully schedulable hot water sanitizable standard for RO system

- UV sanitizable carbon filter

- Full perimeter stainless steel framing for ease of installation and protection

- Backed by manufacturer's warranty

- Common “off-the-shelf” control system

- Dual input filters and water softeners

- Redundant RO feed pumps

- Adjustable feet standard

- Customizable features include:

- Component manufacturers

- Programming

- Additional or limited instrumentation

- Network interfacing

- Sanitization methods

- Break tank size

- Interface with other Mueller equipment

- Power input capabilities

- UPS capabilities

- Modularity

-

Specifications

- Sizes

- 5, 10, 20, 30 and 50 GPM WFI systems

- Models

- PT-RO-UF-5 through 50 (full system)

- PT-10 through 100 (pretreatment only)

- RO-5 through 50 (RODI skid only)

- UF-5 through 50 (UF skid only)

- PT-RO-UF-5 through 50 (full system)

- Sizes

-

- MTI Shipping Solutions Brochure Download MTI Shipping Solutions Brochure Learn More MTI Shipping Solutions Brochure

- BioPharmaceutical Systems At-a-Glance - Paul Mueller Company Download BioPharmaceutical Systems At-a-Glance - Paul Mueller Company Learn More BioPharmaceutical Systems At-a-Glance - Paul Mueller Company

- Paul Mueller Company Capabilities - Paul Mueller Company Download Paul Mueller Company Capabilities - Paul Mueller Company Learn More Paul Mueller Company Capabilities - Paul Mueller Company

Features

- Modularity

- Pretreatment (softener) skid includes dual pre-filters, dual softeners, a carbon filter, a UV light, and break tank

- RO and CEDI skid includes RO pre-filter, dual RO pumps, RO housings and membranes, and CEDI

- UF skid includes ultrafiltration (UF) and ultraviolet (UV)

- System can be purchased separately or as one system

- UF skid designed to fit within RO skid for footprint minimization

- Can oversize portions of the system to branch off the RO or softener system and feed other utilities in the facility if needed

- One centrally located control system

- UL508A Certified

- Distributed I/O capabilities

- Industrial hardened Ethernet backbone

- Fully supported by factory-certified service technicians

- Supported by in-house ISO 17025 calibration lab with onsite services

- Designed for sustainability

- Designed for pharmaceutical applications, including hot water sanitizable RO membranes

- Integrated control system controls the entire system and interfaces with other Mueller® water and steam systems

- No plant steam or coolant needed

- Includes recycling of water within the skid to minimize waste

- Fully operational, skidded, and tested at factory

- Reduces start-up time and site installation

- Factory performance tested

- Full pharmaceutical turnover package (TOP)

- Chemical-fee polypropylene butt-fusion welding for pretreatment skid

- Dual filters and softener tanks for a continuous supply of softened water for carbon & UV treatment in PT system

- Automated softening, carbon, & UV valving system based on defined water criteria

- Stainless steel tubing 25RA (SF2) for RO system & 20RA EP (SF5) for UF system

- Fully schedulable hot water sanitizable standard for RO system

- UV sanitizable carbon filter

- Full perimeter stainless steel framing for ease of installation and protection

- Backed by manufacturer's warranty

- Common “off-the-shelf” control system

- Dual input filters and water softeners

- Redundant RO feed pumps

- Adjustable feet standard

- Customizable features include:

- Component manufacturers

- Programming

- Additional or limited instrumentation

- Network interfacing

- Sanitization methods

- Break tank size

- Interface with other Mueller equipment

- Power input capabilities

- UPS capabilities

Specifications

- Sizes

- 5, 10, 20, 30 and 50 GPM WFI systems

- Models

- PT-RO-UF-5 through 50 (full system)

- PT-10 through 100 (pretreatment only)

- RO-5 through 50 (RODI skid only)

- UF-5 through 50 (UF skid only)

- PT-RO-UF-5 through 50 (full system)

- MTI Shipping Solutions Brochure Download MTI Shipping Solutions Brochure Learn More MTI Shipping Solutions Brochure

- BioPharmaceutical Systems At-a-Glance - Paul Mueller Company Download BioPharmaceutical Systems At-a-Glance - Paul Mueller Company Learn More BioPharmaceutical Systems At-a-Glance - Paul Mueller Company

- Paul Mueller Company Capabilities - Paul Mueller Company Download Paul Mueller Company Capabilities - Paul Mueller Company Learn More Paul Mueller Company Capabilities - Paul Mueller Company