-

Features

- Eliminates the need for a process pump and external heat exchanger

- High operating pressures

- High operating temperatures

- No gaskets required

- Corrosion resistant

- Easily formed to fit the shape you need

- Cutouts are easily provided

- Food-grade designs available

- Variety of Finishes

- Thermally efficient types of heat transfer:

- Immersion heating and cooling

- Clamp-on heating, cooling, and temperature maintenance

- Integral jacketing for heating and cooling

- Custom heat exchanger design

- Evaporators

- Condensers

- Easily cleanable

- Low-pressure drop design

-

Specifications

Work with our innovative engineers to create a perfect system for you and your facility. At Paul Mueller Company, we work to meet all your needs, and with our various shapes, sizes, and specifications, we are confident that we will be able to make a high-quality product that you will love.

-

- MTI Shipping Solutions Brochure Download MTI Shipping Solutions Brochure Learn More MTI Shipping Solutions Brochure

- Temp-Plate® Panel Design Form Download Temp-Plate® Panel Design Form Learn More Temp-Plate® Panel Design Form

- All About Temp-Plate® Brochure Download All About Temp-Plate® Brochure Learn More All About Temp-Plate® Brochure

- Paul Mueller Company Capabilities - Paul Mueller Company Download Paul Mueller Company Capabilities - Paul Mueller Company Learn More Paul Mueller Company Capabilities - Paul Mueller Company

-

Financing Your Equipment Needs

Are you getting ready to open a a new business or are you looking to replace or expand your existing footprint? Paul Mueller Company offers a large array of products from farm to pharmaceutical and everything in between. Equipment financing is a great way to get the funds you need now without using up your credit line or working capital.

Why Finance?

- Free up working capital

- Gain tax advantages

- Match payments to cash flow

- 100% financing, including shipping and installation

- Competitive Rates

- Fast and liberal credit decisions

- Simple online application

- No obligation, no risk

Features

- Eliminates the need for a process pump and external heat exchanger

- High operating pressures

- High operating temperatures

- No gaskets required

- Corrosion resistant

- Easily formed to fit the shape you need

- Cutouts are easily provided

- Food-grade designs available

- Variety of Finishes

- Thermally efficient types of heat transfer:

- Immersion heating and cooling

- Clamp-on heating, cooling, and temperature maintenance

- Integral jacketing for heating and cooling

- Custom heat exchanger design

- Evaporators

- Condensers

- Easily cleanable

- Low-pressure drop design

Specifications

Work with our innovative engineers to create a perfect system for you and your facility. At Paul Mueller Company, we work to meet all your needs, and with our various shapes, sizes, and specifications, we are confident that we will be able to make a high-quality product that you will love.

- MTI Shipping Solutions Brochure Download MTI Shipping Solutions Brochure Learn More MTI Shipping Solutions Brochure

- Temp-Plate® Panel Design Form Download Temp-Plate® Panel Design Form Learn More Temp-Plate® Panel Design Form

- All About Temp-Plate® Brochure Download All About Temp-Plate® Brochure Learn More All About Temp-Plate® Brochure

- Paul Mueller Company Capabilities - Paul Mueller Company Download Paul Mueller Company Capabilities - Paul Mueller Company Learn More Paul Mueller Company Capabilities - Paul Mueller Company

Financing Your Equipment Needs

Are you getting ready to open a a new business or are you looking to replace or expand your existing footprint? Paul Mueller Company offers a large array of products from farm to pharmaceutical and everything in between. Equipment financing is a great way to get the funds you need now without using up your credit line or working capital.

Why Finance?

- Free up working capital

- Gain tax advantages

- Match payments to cash flow

- 100% financing, including shipping and installation

- Competitive Rates

- Fast and liberal credit decisions

- Simple online application

- No obligation, no risk

Specific Applications

Freeze Drying Equipment

Utilized primarily in the food processing, pharmaceutical, cosmetics, and pet food industries, freeze-drying is used to dehydrate a product to extend its shelf life. The process starts with the product being rapidly frozen and then placed in a vacuum chamber where pressure is reduced. Heat is also applied to the product as pressure decreases, and the ice sublimates (changes directly from solid to gas state), removing most of the water.

Tray Assemblies

Temp-Plate can be used in this application as direct contact heat transfer shelves. Designed for vacuum environments, our single embossed Temp-Plate panels create a flat surface for the product to lay on and directly transfer heat to sublimate the liquid out of the products. Designed specifically for your application:

- Tight flatness tolerance to provide direct contact between the heating panel and the product

- Sanitary surface finishes can be provided on the product contact side of the panels crucial for pharmaceutical or food industries

- Exterior edges of the heating plates can be seal welded to prevent media outgassing due to the vacuum environment, thus protecting your product

Condensing Banks

After the product has been dried, Temp-Plate can also be used as a condensing unit for the vapor that has been sublimated from it.

The water vapor is directed to the chilled condenser, which causes ice to form on the exterior surface of the panels. The condensing unit is crucial to freeze drying as it prevents the water vapor from returning to the vacuum chamber and affects drying cycle times.

Bayonet/Insertion Heaters

Bayonet heaters are a specialized form of Temp-Plate bank assembly designed to be mounted on a blind flange. The blind flange aligns with and connects to an existing manway on the tank, allowing for a seamless installation.

One key benefit of this setup is that it moves the supply and return connections external to the tank, simplifying the piping system. This design provides a more straightforward and efficient solution than internal pipe coils.

Geothermal Heat Recovery

Temp-Plate assemblies can be installed in hot springs to capture the natural thermal energy of the spring. Thermal energy is used to melt snow from pedestrian pathways and heat domestic hot water for sinks and showers to save energy costs.

Due to the mineral-rich composition of spring water, Temp-Plate bank assemblies can be constructed using titanium or other corrosion-resistant alloys. Additionally, given its application for domestic potable water, the Temp-Plate system can be designed to meet double-wall heat exchanger specifications, ensuring the safety of tenants by preventing potential contamination.

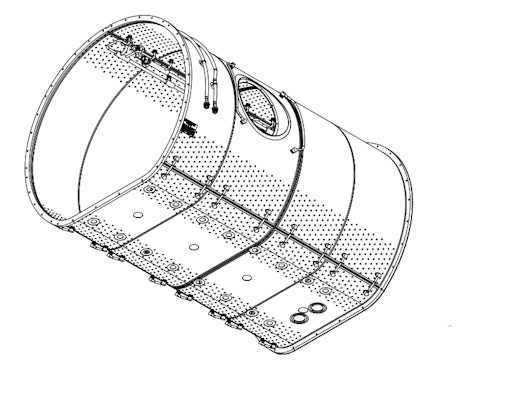

Cryo Shrouds

Aerospace components must undergo a series of rigorous testing phases to ensure they can withstand the intense conditions of outer space, including extreme temperatures, radiation, and vacuum.

These tests are crucial to verify their durability, functionality, and reliability, as failures could have catastrophic consequences for both the mission and the equipment involved. Temp-Plate has been used as a cryo shroud to simulate the space environment to ensure accurate testing. The space environment is created by circulating liquid nitrogen through the Temp-Plate cryo shroud in a vacuum chamber. Testing has been performed on satellites, power sources, and other communication devices using the Temp-Plate cryo shroud below.

Heat Shields for Induction Furnaces

Temp-Plate made from high-temperature alloys, e.g., Alloy 20, is ideal for use as a heat shield in induction furnaces.

These durable materials effectively protect critical components, such as bearings, from extreme heat, significantly reducing wear and tear. Temp-Plate helps extend the overall lifespan of the machine by shielding heat-sensitive parts, ensuring more reliable performance and reducing maintenance costs over time.

Food Processing

Trough Assemblies

A standard Temp-Plate design in food processing equipment is heated trough assemblies. Constructed out of single-embossed panels, this heat transfer surface features a smooth product contact side for seamless integration into your machinery.

Traditionally, such systems would be fabricated by welding a dimple jacket onto the structure. However, Temp-Plate offers the advantage of integrating heat transfer functionality directly into the trough wall, eliminating the need for additional components. By incorporating Temp-Plate into your system, you can reduce material costs, as the heat exchanger is built into the assembly wall, and minimize installation labor compared to traditional dimple jacketing. Temp-Plate jackets are available as individual panel sections or fully assembled units, with end plates tailored for easy integration into your system.

Fryer Banks

A fryer bank assembly is another custom application of Temp-Plate in food processing equipment. Ready for custom integration into industrial OEM fryer equipment, Temp-Plate is an ideal solution to help process thousands of pounds of product daily.

It provides highly efficient heat transfer, ensuring consistent temperature control for frying while maintaining food safety standards with its food-grade design. The heat exchanger's compact, low-height configuration makes it a perfect fit under the conveyor system in the fryer, optimizing space and streamlining the production process. Its durability and energy efficiency support high-volume processing, enhancing the overall performance and reliability of the fryer system.

Pond/Lake Immersion Assemblies

Thermal Heat Sink

A Temp-Plate bank assembly can be installed in ponds or lakes as a thermal heat sink, efficiently pre-cooling water that HVAC systems have heated. By using the natural cooling properties of bodies of water, this setup reduces the workload on chiller systems, ultimately saving money on energy and operating costs. Both residential and commercial areas can take advantage of nearby lakes or ponds, tapping into this eco-friendly solution to lower HVAC system expenses. The heat exchanger can also be designed with titanium panels or other corrosion-resistant alloys, making it suitable in saltwater environments.

Log Pond Heating

Temp-Plate is an excellent solution for log pond heating, as it can efficiently maintain elevated temperatures crucial for debarking. By regulating and evenly distributing heat throughout the pond, Temp-Plate ensures that the logs stay at the optimal temperature, making the debarking process smoother and more efficient. This consistent heat helps soften the bark, allowing for easier removal and improving the overall efficiency of the operation.

Evaporator Pans for Paper Processing

In paper processing plants, the high levels of moisture in the air from various steam-based operations often lead to condensation, causing water to drip down from the ceilings.

This moisture poses a risk to the delicate paper products, potentially causing tears and damage when spanning gaps between rolls. Temp-Plate can be used as a protective measure between these gaps. By feeding steam into Temp-Plate, it instantly evaporates any dripping moisture, ensuring that the paper remains protected and free from tears, preserving its integrity throughout the processing stages.

How to Order

To receive a quotation for a Temp-Plate application, please use the design sheet linked below. Fill out as many details on your project as possible, and submit using our contact form. Our sales and engineering team is dedicated to contacting you promptly afterward to turn your vision into a reality.