XL Robotic Milking

Cooling Solutions for 720+ Cows

The Future is Here

It was only a matter of time before commercial dairies invested in voluntary milking systems. These systems help eliminate inconsistencies in on-farm labor costs and procedures. Mueller's cooling and storage solutions work in unison with voluntary milking systems to help protect profits amidst the 24/7 seven-hustle of extra-large robotic dairies.

XL Dairies = Custom Solutions

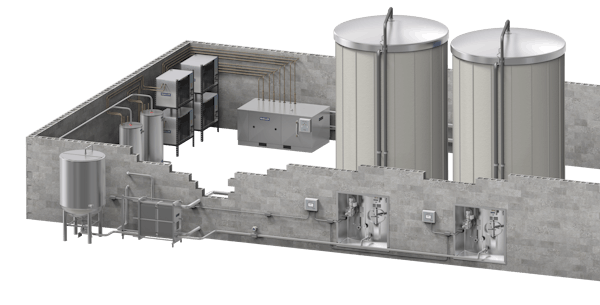

When your robotic project exceeds 12 milking stalls, your setup becomes unique to your facility and layout. We have an extra-large robotic cooling solution at Paul Mueller Company to handle your expansion. Our design specialists collaborate with your team to create an ideal system, including the milk transfer system, the instant chiller(s)/plate cooler, the on-farm storage vessel, the milk hauler interface, and the clean-in-place (CIP) wash system. The goal is to get the most out of every day and every robot. Mueller's milkhouse solutions help minimize your downtime.

Built for Expansion

As dairy producers think long-term about future growth, you will likely see more robotic dairies worldwide. Robotic dairies allow dairy producers more time for things they are passionate about: herd health, milk quality, genetics, etc. This way of life also promotes flexibility in a dairy producer's daily operations, with more quality time for family and friends. At Paul Mueller Company, we support your efforts with the most efficient dairy storage and cooling equipment available. When designing a robotic dairy farm, consult your local Mueller-Certified Dealer to build the right robotic milk cooling solution for you.

Features at a Glance

- 720+ Cows

- On-Farm Milk Storage

- Instant Cooled Milk

- Energy-Efficient E-Star® HiPerForm® Technology

- RIC (Robotic Interface Control)

- Industry Preferred Clean-In-Place Wash System

- Nimbus Cooling and Wash Control

- Free Hot Water with Mueller's Model D Fre-Heater®

- Dedicated Technical Service Hotline and Experienced Sales Force