The Hot and The Cold of it

Calculating Needs

The right heat transfer equipment can mean a faster workflow, more sustainable processes, and savings to your bottom line, but you must know how to calculate your needs correctly. That's where we can help.

Any Volume, Any Liquid

Our highly versatile heat transfer surface can quickly change the temperature of any volume or type of liquid you need. From clamp-on sections and jacketed sheets to cones, chutes, banks, and immersion panels, we can design, engineer, and manufacture the right shape and size for your process.

Enhanced Alternatives to Shell and Tube

While shell and tube heat exchangers are most commonly taught to students in many engineering curriculums, changes in technology and innovation have brought about more efficient solutions. At Paul Mueller Company, we have 80 years of heat transfer and processing experience under our belts, and we know which heat transfer works best for which applications. Whether it's:

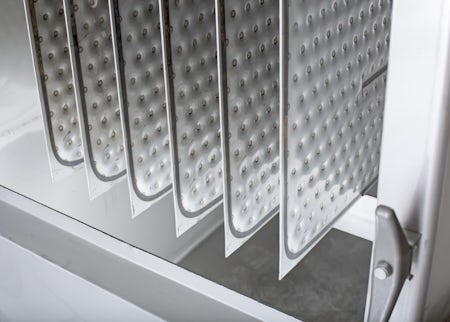

- Inflated Temp-Plate® requires significantly less space and minimizes the chance of fouling, all while providing efficient heat transfer rates in high-pressure or corrosive environments

- Plate Heat Exchangers achieve the closest possible approach temperatures and are more economical than other types of heat exchangers due to the higher thermal efficiency and lower manufacturing costs

- Custom Stamped Dimple Plate is ideally suited for applications involving high pressure and temperature extremes

- Half-pipe coil handles large flow volumes effectively and great for cyclic heat transfer conditions

Simple or Complex Engineering

Are you unsure what kind of heat transfer you need? Let us help. Our engineers are ready to listen to your application and parameters and help you choose the best type and size for your application.

Features at a Glance

- Highly Versatile

- Works with all Mediums

- High Pressure applications

- Low-Pressure drops

- Welded, Formed or Fitted

- Multitude of Shapes

- Easy Cleanability

- Food Grade available

- ASME Code available

- Variety of Finishes

- Double or Single Embossed

- Reduced Condensate Build-up

- Free Flow Pattern

- Service and Repair

- Parts