-

Benefits of Clamp-on Temp-Plate

- Easy add-on for retrofitting an existing tank with heating or cooling with minimal to no downtime

- Indirect tank heating means no concern for material compatibility with processes or panel corrosion

- No interference with internal tank mixing components

- Temp-Plate panel design provides a much more uniform heating surface over other heat-tracing products

When to Use Clamp-on Temp-Plate?

- When a process needs to be maintained at a specific Temperature

- Light-duty heat up or cooldown of process inside the tank

- Minimum wall temperature maintenance

- Freeze protection in cold climate conditions

Applications

The applications that Temp-Plate can be used in are practically endless. The list below is just to name a few. If you have a heating or cooling need, our team of dedicated engineers are ready to help design a solution for you. Check out some of our other related product pages for more in depth information on how Temp-Plate can be used.

- Vertical or Horizontal Storage tank temperature maintenance

- Dished/Conical head coverage: maintain process heating to the process drain connection to limit cold spots

- Offsetting heat-gain or loss in reaction processes

- Sulphur tanks: maintenance of wall temperature to prevent corrosive sulphuric acid condensation building up on the internal wall surfaces

- Cold Climates: freeze protection for outdoor tanks or 8” diameter or larger pipe runs

-

Material Types

Corrosion or product compatibility concerns are no issue with external clamp-on jackets. Clamp-on Temp-Plate panels are primarily provided in 304 or 316 stainless steel or carbon steel. If you have a special alloy tank, we can provide the tank lugs to be welded to your vessel in the desired material, while supplying the panels in a more cost effective alloy.

Material Thickness

Below are the commonly used material thickness combinations available for Temp-Plate. Double embossed Temp-Plate is usually recommended for clamp-on applications as the heat transfer mastic closes any air gaps between the panel’s inflated pillows and the vessel wall. Double embossed panels also have lower material costs compared to our single embossed offering. .

Double Embossed

- 20GA / 20GA

- 18GA / 18GA

- 16GA / 16GA

- 14GA / 14GA

- 12GA / 12GA

- 10GA / 10GA

Panel Sizes

Depending on material type and thicknesses, a single Temp-Plate panel can be fabricated in sizes up to 60” x 240”. Based on material type and application, special sizes can be supplied.

Heating or Cooling Mediums

Temp-Plate can be used with a wide range of heating or cooling media based on the utilities you have available. For heating, steam, hot water, ethylene or propylene glycol or heat transfer oils are the common fluids. For cooling, chilled water, glycol, or direct expansion refrigerants are the common fluids.

Design Pressure & Temperatures

As a standard, Temp-Plate is ASME code rated to a 150psi design pressure at 400°F / -20°F. For high-pressure applications, Temp-Plate can withstand pressures exceeding 2,000 psi.

Qualifications

- ASME code ‘UM’ or ‘U’ stamp

- CRN

- PED

-

- MTI Shipping Solutions Brochure - Paul Mueller Company Download MTI Shipping Solutions Brochure - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - Paul Mueller Company

- Temp-Plate® Panel Design Form Download Temp-Plate® Panel Design Form Learn More Temp-Plate® Panel Design Form

- Double-Embossed Clamp-On Temp-Plate® Brochure Download Double-Embossed Clamp-On Temp-Plate® Brochure Learn More Double-Embossed Clamp-On Temp-Plate® Brochure

- All About Temp-Plate® Brochure Download All About Temp-Plate® Brochure Learn More All About Temp-Plate® Brochure

- Paul Mueller Company Capabilities - Paul Mueller Company Download Paul Mueller Company Capabilities - Paul Mueller Company Learn More Paul Mueller Company Capabilities - Paul Mueller Company

-

Financing Your Equipment Needs

Are you getting ready to open a a new business or are you looking to replace or expand your existing footprint? Paul Mueller Company offers a large array of products from farm to pharmaceutical and everything in between. Equipment financing is a great way to get the funds you need now without using up your credit line or working capital.

Why Finance?

- Free up working capital

- Gain tax advantages

- Match payments to cash flow

- 100% financing, including shipping and installation

- Competitive Rates

- Fast and liberal credit decisions

- Simple online application

- No obligation, no risk

Benefits of Clamp-on Temp-Plate

- Easy add-on for retrofitting an existing tank with heating or cooling with minimal to no downtime

- Indirect tank heating means no concern for material compatibility with processes or panel corrosion

- No interference with internal tank mixing components

- Temp-Plate panel design provides a much more uniform heating surface over other heat-tracing products

When to Use Clamp-on Temp-Plate?

- When a process needs to be maintained at a specific Temperature

- Light-duty heat up or cooldown of process inside the tank

- Minimum wall temperature maintenance

- Freeze protection in cold climate conditions

Applications

The applications that Temp-Plate can be used in are practically endless. The list below is just to name a few. If you have a heating or cooling need, our team of dedicated engineers are ready to help design a solution for you. Check out some of our other related product pages for more in depth information on how Temp-Plate can be used.

- Vertical or Horizontal Storage tank temperature maintenance

- Dished/Conical head coverage: maintain process heating to the process drain connection to limit cold spots

- Offsetting heat-gain or loss in reaction processes

- Sulphur tanks: maintenance of wall temperature to prevent corrosive sulphuric acid condensation building up on the internal wall surfaces

- Cold Climates: freeze protection for outdoor tanks or 8” diameter or larger pipe runs

Material Types

Corrosion or product compatibility concerns are no issue with external clamp-on jackets. Clamp-on Temp-Plate panels are primarily provided in 304 or 316 stainless steel or carbon steel. If you have a special alloy tank, we can provide the tank lugs to be welded to your vessel in the desired material, while supplying the panels in a more cost effective alloy.

Material Thickness

Below are the commonly used material thickness combinations available for Temp-Plate. Double embossed Temp-Plate is usually recommended for clamp-on applications as the heat transfer mastic closes any air gaps between the panel’s inflated pillows and the vessel wall. Double embossed panels also have lower material costs compared to our single embossed offering. .

Double Embossed

- 20GA / 20GA

- 18GA / 18GA

- 16GA / 16GA

- 14GA / 14GA

- 12GA / 12GA

- 10GA / 10GA

Panel Sizes

Depending on material type and thicknesses, a single Temp-Plate panel can be fabricated in sizes up to 60” x 240”. Based on material type and application, special sizes can be supplied.

Heating or Cooling Mediums

Temp-Plate can be used with a wide range of heating or cooling media based on the utilities you have available. For heating, steam, hot water, ethylene or propylene glycol or heat transfer oils are the common fluids. For cooling, chilled water, glycol, or direct expansion refrigerants are the common fluids.

Design Pressure & Temperatures

As a standard, Temp-Plate is ASME code rated to a 150psi design pressure at 400°F / -20°F. For high-pressure applications, Temp-Plate can withstand pressures exceeding 2,000 psi.

Qualifications

- ASME code ‘UM’ or ‘U’ stamp

- CRN

- PED

- MTI Shipping Solutions Brochure - Paul Mueller Company Download MTI Shipping Solutions Brochure - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - Paul Mueller Company

- Temp-Plate® Panel Design Form Download Temp-Plate® Panel Design Form Learn More Temp-Plate® Panel Design Form

- Double-Embossed Clamp-On Temp-Plate® Brochure Download Double-Embossed Clamp-On Temp-Plate® Brochure Learn More Double-Embossed Clamp-On Temp-Plate® Brochure

- All About Temp-Plate® Brochure Download All About Temp-Plate® Brochure Learn More All About Temp-Plate® Brochure

- Paul Mueller Company Capabilities - Paul Mueller Company Download Paul Mueller Company Capabilities - Paul Mueller Company Learn More Paul Mueller Company Capabilities - Paul Mueller Company

Financing Your Equipment Needs

Are you getting ready to open a a new business or are you looking to replace or expand your existing footprint? Paul Mueller Company offers a large array of products from farm to pharmaceutical and everything in between. Equipment financing is a great way to get the funds you need now without using up your credit line or working capital.

Why Finance?

- Free up working capital

- Gain tax advantages

- Match payments to cash flow

- 100% financing, including shipping and installation

- Competitive Rates

- Fast and liberal credit decisions

- Simple online application

- No obligation, no risk

Competitor vs Mueller Temp-Plate Heat Map

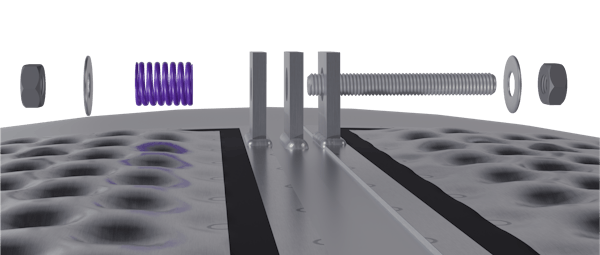

Installation

Paul Mueller Company is dedicated to making the installation of Clamp-on Temp-Plate jackets as simple as possible. As a standard, our quotes will include all of the required hardware and factory applied heat transfer mastic to the panels so your installation is complete in 3 simple steps:

- With the plastic covering still attached, align the Temp-Plate panel in the proper location and mark the locations for the installation of the tank mounting lugs

- Remove Temp-Plate panel and weld the tank mounting lugs in position

- Remove the protective plastic covering and mount the panels using the provided spring-bolt assemblies

Note: Pre-applied mastic is only available when the design temperature is 450°F or below. When the design temperature exceeds 450°F, Paul Mueller Company will still provide a quote with loose buckets of hardening heat transfer mastic that will need to be applied to the panels prior to step 1 above.

When welding lugs to your tank is not acceptable, please let us know and we will work with you on suggesting alternative options.

Installation Diagrams

How to Order

To receive a quotation for a Temp-Plate application, please use the design sheet linked below. Fill out as many details on your project as possible, and submit using our contact form. Our sales and engineering team is dedicated to contacting you promptly afterward to turn your vision into a reality.