The Many Uses of Custom Heat Transfer

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

- Heat Transfer

- January 30, 2021

- 5 Minute Read

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

Space-Saving, Easy-to-Install Solutions

A custom heat transfer surface may be the answer if you face heating or cooling challenges. Custom Temp-Plate® inflated heat transfer panels are often the best solution for passive temperature control of stored liquids. Immersed plate sections of spot-welded heat transfer can also provide a space-saving, easy-to-install solution. When discussing high pressures and temperature extremes, a stamped dimple plate can be customized for any type of storage tank, shell, or cone and welded directly on, like a jacket. Finally, the half-pipe coil is appropriate for high-pressure applications and low-pressure drop requirements, and it can handle large volumes of liquid. The versatility of custom heat transfer allows you to get exactly what you need to ensure efficient workflow, sustainable processes, and, ultimately, increased cost savings.

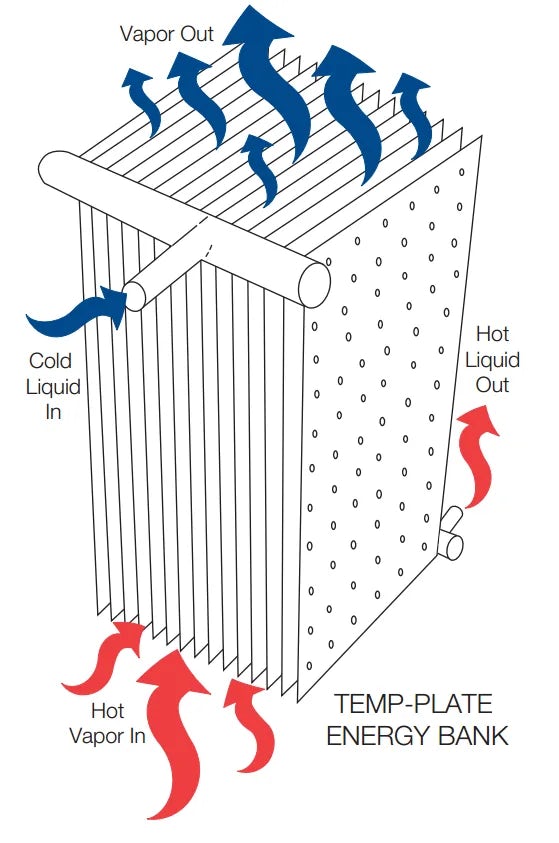

Temp-Plate® Energy Recovery Banks

If your process vents exhaust into the atmosphere or loses heat in some other way, then Waste Heat Recovery provides an energy-saving solution by allowing you to capture the lost energy and reuse it. A processing plant in Alabama using thermal oxidizers to process the plant’s gas emissions in compliance with environmental regulations was experiencing a huge waste of high-grade heat when the exhaust gas from the oxidizers was being released into the atmosphere. At the same time, the plant was paying more than a million dollars each year for steam to heat their incoming process fluid. By installing a Temp-Plate® energy recovery bank to capture the exhaust and use it to heat the steam, we could save them more than a million dollars, meaning making more money towards their bottom line, year after year for a one-time cost of $460,000 (for installation plus equipment).

Projects in the field of condensation, evaporation, or heat recovery that need high energy efficiency or feasibility in extreme conditions can also take advantage of Temp-Plate® energy banks. The chemical industry sees the benefits of condensing with Temp-Plate® modules at low absolute pressure, a specialty developed by our German engineering company, DEG Engineering GmbH. This case study shows how DEG's process knowledge and Mueller's Temp-Plate® technology helped a refinery in India source efficient heat transfer equipment to provide very specific high heat loads, organized to an optimized flow geometry, producing high condensation rates.

Tanks & Heads

When you need to cool or heat the content of your tanks, our stamped dimple plate heat transfer surface is ideally suited for applications involving high pressure and temperature extremes. It can be routinely fabricated in an almost unlimited number of shapes, sizes, and materials to fit any vessel design. Styles are available for use with almost any refrigerant or heating media type.

A half-pipe welded onto the outside of a tank head/shell is called a "half-pipe jacket. Mueller half-pipe coil heat transfer surface handles large volumes of flow and is suited for high-pressure applications and low-pressure drop requirements. It is ideal for cyclic heat transfer conditions where heating and cooling cycles occur several times daily as it is very resistant to stress corrosion cracking. A half-pipe coil is used for heating or cooling with steam, hot oil, water, glycol, ammonia, and refrigerants. ASME code stamping is available.

Machine Oil Cooling

Oil is commonly used as a lubricant or cooling medium in machining processes. Oil is also very susceptible to contamination, and, due to its effectiveness as a cooling medium, becomes hot easily. Generally, a traditional shell-and-tube heat exchanger is used to remedy this issue but comes with its own set of issues. Since shell-and-tube heat exchangers are difficult to clean, dirty oil will render them useless over time requiring constant maintenance.

Since tanks are much easier to clean and remove from service, the best solution to this issue is to run the dirty oil through a holding tank so that the contaminants can settle to the bottom, preventing the outflow from clogging a heat exchanger.

This assembly also includes a tank to filter the oil before running it through the heat exchanger. However, this is more expensive because it involves an additional component. By using Temp-Plate® panels in the form of an immersed plate or a tank jacket, it would be possible to have the functionality of a heat exchanger at a much lower price point without the risk of clogging.

Two of our customers, a Tennessee chainsaw blade manufacturer, and a Missouri-based clay pigeon manufacturer, used Temp-Plate® in this way to improve their efficiency. The Tennessee company passed their cutting oils through a tank fitted with a bank of immersed Temp-Plate® sections and used an agitator to suspend iron filings. This allowed them to avoid cleaning them out manually. The Missouri company ordered custom shapes of Temp-Plate® to facilitate an intermediate fluid (ethylene glycol), preventing dirty oil from plugging up their process. By using the Temp-Plate® in conjunction with an existing heat exchanger, they could easily clean their system, significantly reducing downtime.

While machine oil cooling is a common application, this solution works in any situation where particulates can impede the process stream.

Clamp On Applications

One of the applications that makes custom heat transfer so versatile is the clamp-on, where standard or custom-sized plates can be clamped onto a vessel. A clamp-on application's greatest benefit is its ability to install within an existing process. Sometimes, as a process evolves, the need for a heat exchanger develops, but the floor plan may not have sufficient room for one. Custom heat transfer can be clamped onto an existing vessel to serve as a heat exchanger without taking up any extra space.

Becon Engineering from Houston is a great example of this application. Becon was working on a project for Chevron, which required hot water for a demineralized water dilution heater in the middle of the oil refining process. Because no nearby power source was available to supply the hot water, Becon clamped 51 square feet of Temp-Plate® to a 14” high-pressure steam line—the only available heat source. In this case, Temp-Plate® offered an engineering firm the flexibility to solve an otherwise expensive problem economically.

Another advantage of Temp-Plate® is that it can withstand very high pressures (up to 1500 psig). Brown & Root Engineering, another Houston customer, needed to keep a salt storage tank at 400ºF with 600 psig steam at 486ºF. With the right specifications, Temp-Plate® easily achieved those marks. You can use the customized inflated heat transfer to change the application of industrial tanks from one use case to another.

Conclusion

Sometimes, heat exchange processes require creativity, and Paul Mueller Company Temp-Plate®, dimple plate, and half-pipe coil provide flexibility and cost savings for custom heat transfer solutions in various applications.

More from Mueller Academy

- Introducing Our New Membrane-Based Water for Injection (WFI) Skids

- Manway Gasket Installation & Bushing Adjustment

- How to Decide Between a Horizontal & Vertical Milk Tank

- MES & PSG Feedwater Quality Requirements

- On-Site Tank Fabrication Under Deadline

- Finding the Right Finish: Understanding Polishing

- Increase the Capacity of Your Clean Utility Equipment

- Balancing a Mueller Multiple Effect Still (MES)

- The Different Types of Steam in Industrial Steam Generation