Balancing a Mueller Multiple Effect Still (MES)

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

- Pharmaceutical

- February 16, 2022

- 8 Minute Read

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

Introduction

Ensuring a Mueller Multiple Effect Still (MES) operates at peak performance starts with proper balancing—a key to unlocking its full potential. A well-balanced MES delivers steady benefits: it maintains a constant feedwater supply, which provides about half the condenser’s cooling, ensuring reliable temperature control. Plus, it minimizes annoying alarms—like high effect levels, elevated distillate temps, or analyzer faults—for smoother operation.

An MES is perfectly balanced when it meets or exceeds its Water for Injection design capacity, effect levels hover at or just above overflows, and feedwater flows consistently. When these align, expect stable temperatures and seamless performance.

1. Determine Appropriate First Effect Temperature Setpoint

Most Mueller Multiple-Effect Stills are controlled by the first-effect temperature. Some units are controlled by the first-effect pressure, but since the relationship between pressure and temperature of saturated steam is known, these two control approaches are the same and can be treated as such.

The first effect temperature is one of the primary driving forces determining the operational capacity of the unit. The unit orifice disk sizing is secondary. First, you will need to verify that the orifice disks installed on the unit are appropriate for the capacity of the MES. This can be verified on the unit’s P&ID. If you have questions about orifice disk sizing, consult Mueller Engineering.

A Production Data Report is included in the system turnover package. This is the factory capacity check for the unit. It will give you a good starting point for the first effect temperature setpoint. Using that setpoint, start the unit. Once the first effect is up to temperature and a water level is visible on the effects' flags, check the unit's capacity. If the capacity is too low, raise the first effect temperature setpoint in one or two-degree increments until the correct capacity is reached. If the capacity is too high, lower the first effect temperature setpoint in one or two-degree increments until the correct capacity is reached. During this process, you will likely need to adjust the incoming feedwater to ensure that there is water in all the effects. At this point you are looking for gross adjustments, the feedwater flow will be fine-tuned next.

It may be necessary to change the first effect temperature setpoint later in the process, but note that changing the setpoint will require you to go back through the rest of the balancing procedures.

2. Adjust Feedwater Flow to the Unit

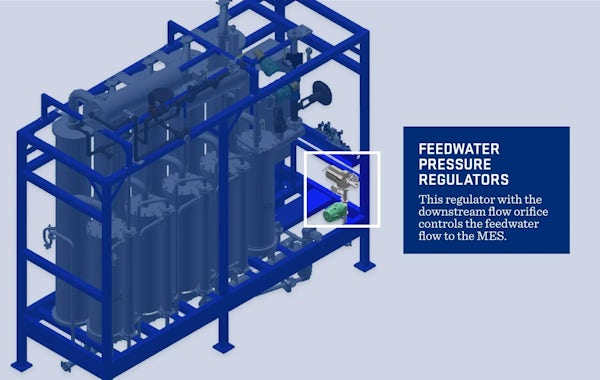

Most Mueller Multiple Effect Stills include a pressure regulator on the feedwater feeding the unit. This regulator, along with an orifice disk just downstream of it, regulates the flow of feedwater to the unit.

A Mueller Multiple Effect Still runs correctly when all of the effects are at roughly the same level (at the overflow), and the feedwater to the unit is constantly on. If the unit has a feedwater pump, that pump should be on continuously when the unit is running. When the unit starts up, it is normal to see some high levels and some cycling of the feedwater to the unit. However, the level should not stay high long enough to cause an alarm, and the cycling of the feedwater should stop after a few cycles.

If, after startup, the feedwater to the unit is cycling on and off due to a high level of one or more effects, then the feedwater to the unit should be reduced. The feedwater pressure regulator should be closed off slightly, reducing the pressure after the regulator. Note that the unit is sensitive to changes in the feedwater pressure, so only small changes should be made. In most cases, quarter or half turns on the pressure regulator should be sufficient to see a change in unit operation. Smaller changes, such as 1/8 or 1/16 turns, may be necessary to fine-tune the balancing of the unit.

If the level in one or more effects is low or not showing on the flag indicators after startup, then the unit feedwater should be increased. The feedwater pressure regulator should be opened up slightly, increasing the pressure after the regulator. Again, small changes should be made to ensure the operation point is not overshot.

3. Monitor Unit Level & Feedwater

After the unit is balanced, it should be monitored to verify that the levels are good, and that the feedwater stays on. If either of these conditions are not met, return to step 2 to further balance the unit. It is quite possible that the unit may take one or more hours to raise or lower the level in an effect, especially if the unit is very close to being balanced.

After the unit is balanced, it should be monitored to verify that the levels are good, and that the feedwater stays on. If either of these conditions are not met, return to step 2 to further balance the unit. It is quite possible that the unit may take one or more hours to raise or lower the level in an effect, especially if the unit is very close to being balanced.

Keeping a Mueller Multiple Effect Still correctly balanced will ensure that the unit produces the design capacity and prevent nuisance alarms due to level or distillate temperature.

More from Mueller Academy

- Introducing Our New Membrane-Based Water for Injection (WFI) Skids

- Manway Gasket Installation & Bushing Adjustment

- How to Decide Between a Horizontal & Vertical Milk Tank

- MES & PSG Feedwater Quality Requirements

- On-Site Tank Fabrication Under Deadline

- Finding the Right Finish: Understanding Polishing

- Increase the Capacity of Your Clean Utility Equipment

- The Different Types of Steam in Industrial Steam Generation

- How a Pure Steam Generator Works